NEOM’s modular success proves industrialised construction is viable

At Saudi Modular Construction Advisory, we’ve seen firsthand how modular construction is no longer a fringe innovation—it’s a strategic necessity. NEOM’s delivery of modular housing for over 3,000 workers, including a six-storey structure completed in just 10 days, is a clear signal: the Gulf is ready to lead the global shift toward industrialised building.

This isn’t just about speed. NEOM is pioneering automated rebar manufacturing, reducing material waste and improving safety—advancing the science of construction itself.

European modular tech finds scale in Saudi Arabia

Across Europe, modular technologies like timber-hybrid systems, robotics, and digital prefabrication platforms often stall due to fragmented regulations and slow procurement. But in Saudi Arabia, they’re gaining traction through strategic joint ventures.

- Casais Entirez, a Portugal–Saudi JV, is deploying Cree GmbH’s modular tech aligned with Vision 2030 goals.

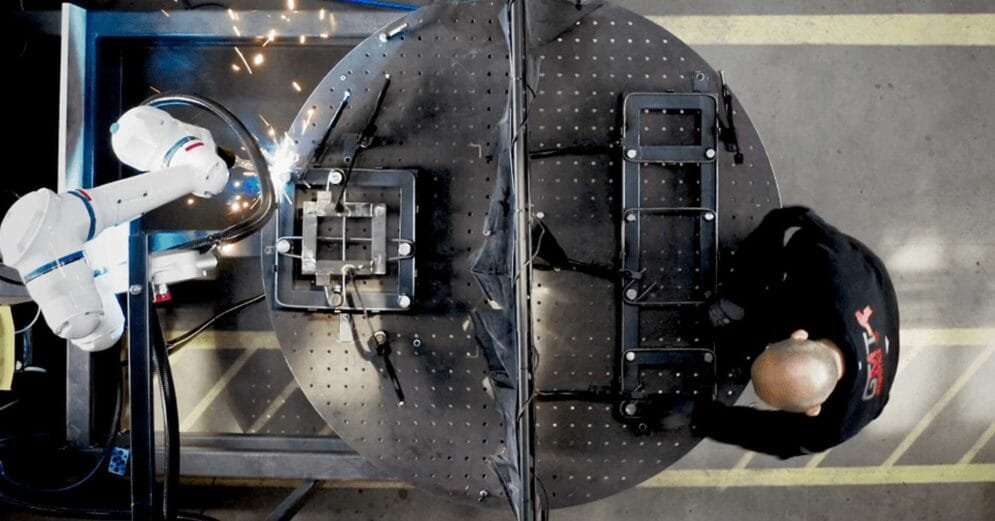

- Denmark’s GMT Robotics, backed by NEOM Investment Fund, automates rebar cage assembly, reducing on-site labor by up to 90%.

- Wolffkran, a German crane manufacturer, partnered with Zamil Group to build 300 cranes in Riyadh, localizing production.

As Saudi Modular Construction Advisory, we view these partnerships as proof that European innovation can scale when embedded in the right ecosystem.

Modular methods cut timelines, waste, and staffing costs

Modern Methods of Construction (MMCs) shift much of the building process off-site, enabling faster, safer, and more sustainable delivery. Globally, modular systems have shown:

- 30–40% faster delivery in Singapore’s Clement Canopy towers

- Up to 8 months saved in California’s affordable housing projects

- 50% reduction in material waste through prefabrication

- 60–70% fewer workplace accidents in controlled environments

In Saudi Arabia, these efficiencies are being applied at giga-project scale, supported by national agendas like Vision 2030 and the UAE’s Industrial Strategy.

Localization drives economic resilience and industrial diversification

Saudi Arabia’s modular strategy isn’t just about importing tech—it’s about embedding it. Factory-built components produced in local plants support regional logistics ecosystems, reduce reliance on foreign labor, and stimulate advanced manufacturing.

This aligns with Vision 2030’s goals of:

- Industrial diversification

- Economic resilience

- Upskilling the workforce

As Saudi Modular Construction Advisory, we help stakeholders integrate small manufacturers and regional suppliers into modular supply chains—turning construction into a strategic industrial pillar.

Modular success depends on early design integration

MMC advantages are diluted when modular principles aren’t embedded from the start. That’s why we advocate for early collaboration using Building Information Modelling (BIM), standardised procurement platforms, and long-term partnerships with modular providers.

Saudi Modular Construction Advisory supports developers, architects, and regulators in transitioning from siloed workflows to integrated delivery models—ensuring modular construction is not a bolt-on, but a foundation.

Also Read: Saudi Construction Industry Transformation: What’s Ahead?