Digital Solutions for Real-Time Construction Site Monitoring in Saudi Arabia

The construction industry in Saudi Arabia is witnessing a transformation with the integration of advanced digital tools that enhance safety, progress tracking, and risk management. With the country’s ambitious Vision 2030 plans to modernize infrastructure and develop smart cities, there has been a growing focus on leveraging digital technology to streamline operations and improve construction site efficiency. This article explores how digital solutions are revolutionizing the construction landscape in Saudi Arabia, particularly in the areas of real-time construction site monitoring, safety improvements, and enhanced project tracking.

Digital Monitoring Tools Enhancing On-Site Safety

One of the most significant challenges in construction is ensuring the safety of workers, especially given the demanding physical conditions on construction sites. In Saudi Arabia, extreme weather conditions, particularly the heat, pose a substantial risk to construction workers. Digital solutions like smart helmets are making a remarkable impact in addressing these safety concerns. For example, the smart helmet developed by Saudi startup WakeCap not only tracks the location and movement of workers but also monitors their health metrics such as temperature and drowsiness. More than 400,000 helmets have been deployed in the region, with over 100,000 workers using them daily.

These helmets provide real-time data that can be used to identify potential hazards and address safety violations. In case of an accident, the helmet’s sensors record the incident, helping employers understand whether proper safety protocols were followed, and whether the worker was authorized to be on site. Such insights are invaluable for accident investigations and improving safety training.

Furthermore, the helmet’s ability to track worker movements helps reduce unauthorized labor on sites, ensuring better supervision and resource management

Also Read: Safety Reinvented: Wearables in the Construction Industry

Progress Tracking and Enhanced Project Management

Construction site monitoring tools also improve the management and progress tracking of projects. Traditionally, contractors relied on manual inspections and reports, which often led to delays and inefficiencies. However, digital solutions now allow for real-time progress tracking using technologies like drones and IoT sensors. These tools provide instant data on the construction process, allowing project managers to assess whether timelines are being met and identify any bottlenecks that could delay the project.

Moreover, AI-driven analytics enable construction managers to predict potential risks before they manifest, whether it’s a delay in material delivery, labor shortages, or potential safety issues. By analyzing historical data, AI systems can identify patterns and forecast problems, enabling proactive solutions rather than reactive measures. This predictive capability helps companies stay on schedule and within budget.

Risk Management and Streamlining Operations

Risk management is another crucial area where digital tools are making a significant difference. Digital risk management platforms allow for seamless communication among all stakeholders in a construction project. Through centralized dashboards, contractors, engineers, and project managers can track progress, manage resources, and address any emerging risks immediately. This integration of data from multiple sources, including sensors, IoT devices, and workforce management systems, allows for more accurate decision-making.

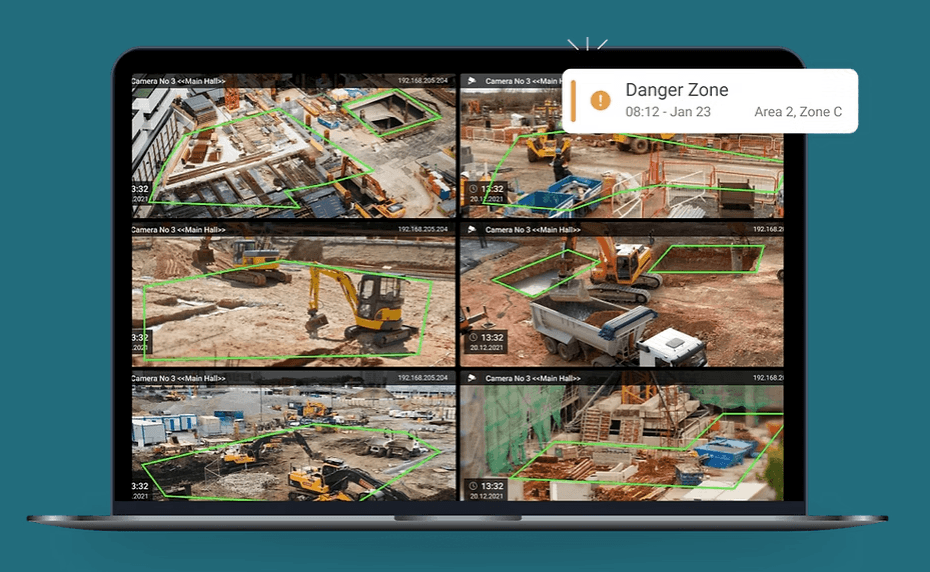

One standout tool in Saudi Arabia is the viAct AI-powered Smart Site Safety System, which is already operational in several major construction projects across the kingdom. This system uses AI algorithms and real-time video analytics to detect safety hazards on-site. It provides instant alerts about unsafe behaviors, PPE (personal protective equipment) non-compliance, and the presence of workers in restricted zones. By identifying these issues immediately, the system enhances overall safety while also improving operational efficiency.

Additionally, the growing use of Digital Twins, or virtual replicas of physical construction sites, is changing how projects are monitored and managed. By integrating real-time data from construction sites into digital models, project managers can simulate different scenarios, optimizing workflows and identifying risks before they affect the actual project.

Also Read: Navigating Saudi Arabia’s Mega Projects with Digital Construction Platforms

Conclusion

The use of digital solutions for construction site monitoring in Saudi Arabia is setting new standards for safety, efficiency, and risk management. With the integration of technologies like smart helmets, AI-driven progress tracking, and predictive analytics, the kingdom’s construction industry is better equipped to handle the complexities of large-scale infrastructure projects. As Saudi Arabia continues to push forward with its Vision 2030 agenda, the adoption of digital tools will play a crucial role in driving the future of construction, ensuring projects are completed safely, on time, and within budget.