Modular Builds Hit 30–40% Faster Delivery in Saudi Arabia

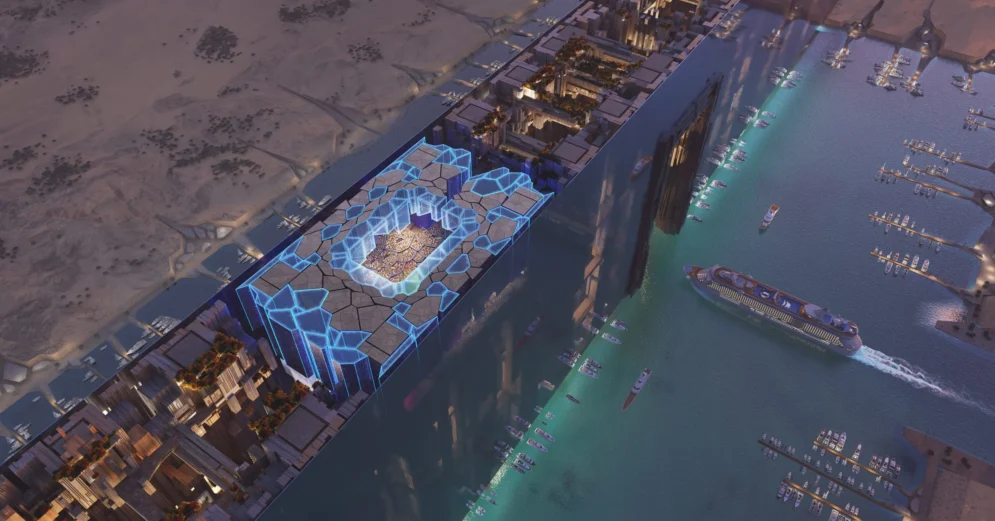

Saudi Arabia’s construction sector is rapidly accelerating through modular innovation, with giga-projects like NEOM proving that industrialised building can redefine speed and scale. One standout: a six-storey modular housing structure completed in just 10 days for over 3,000 workers.

This efficiency—up to 40% faster delivery compared to traditional methods—is attracting attention from global players. Saudi Modular Construction Advisory emphasizes that modular isn’t just quicker—it’s safer and more resource-conscious. Automation in rebar fabrication, for instance, curbs waste and improves site safety, lowering accident rates by 60–70%.

European Modular Tech Gains Traction via Saudi Joint Ventures

Modular technologies across Europe—robotics, hybrid systems, and digital prefabrication platforms—often struggle with fragmented regulations and sluggish procurement. But in Saudi Arabia, strategic partnerships are unlocking scale:

- 🇵🇹 Portugal’s Casais Entirez JV brings Cree GmbH’s modular tech to the Kingdom

- 🇩🇰 Denmark’s GMT Robotics automates rebar cage assembly, reducing manual labor by up to 90%

- 🇩🇪 Germany’s Wolffkran partnered with Zamil Group to build and localize 300 cranes in Riyadh

Saudi Modular Construction Advisory views these alliances as key evidence that European innovation thrives when embedded into Saudi Arabia’s Vision 2030 ecosystem.

Modular Methods Cut Waste by 50%, Staff Costs by 70%

Modern Methods of Construction (MMCs) shift work off-site, enabling dramatic gains in speed, cost, and sustainability. Data from Singapore and California shows up to 8 months saved on project timelines and material waste halved through prefabrication. Saudi projects mirror these results—bringing international standards to local builds.

Saudi Modular Construction Advisory urges developers to integrate MMCs at the design stage. When modular methods are baked in early, instead of added later, timelines shrink and operational headaches disappear.

Localization Strategy Spurs Economic Diversification

Modular construction isn’t just imported—it’s rooted in local industry. Factory-built parts produced within Saudi borders feed regional logistics networks, reduce dependence on foreign labor, and stimulate manufacturing growth. As of 2025, over 300 cranes have been locally produced, streamlining vertical mobility for modular assemblies.

This plays directly into Vision 2030’s industrial goals—diversifying revenue sources, building economic resilience, and upskilling the workforce. Saudi Modular Construction Advisory actively connects small manufacturers to supply chains, making modular a driver of regional empowerment.

Saudi Modular Construction Advisory Pushes Integrated Delivery

Early collaboration and standardisation are essential to maximize modular value. Saudi Modular Construction Advisory champions cross-functional teams using Building Information Modelling (BIM), transparent procurement platforms, and long-term vendor relationships.

Their push? Make modular the foundation—not the afterthought. It’s a mindset shift toward integrated workflows where architects, contractors, and regulators build in sync from day one.

Also Read: European Modular Innovation Finds Scale in $1.3T Saudi Push